New solvent-free activators for metal bonding

Our partner DELO has developed two new activators that accelerate the curing process of DELO-ML metal adhesives. They enable faster production without the use of solvents, which ensures that they comply with occupational safety measures. The activators reduce the curing time of anaerobic adhesives for metal materials. However, for most anaerobic metal adhesives or other reactive adhesives, activators contain solvents. To work, these activators must first be evaporated for a few minutes until the solvent has evaporated and the surface is dry. This is no longer necessary for DELO-QUICK 5910 or its high viscosity version DELO-QUICK 5975. The activator and the adhesive can thus be used using the "Wet on Wet" method without prior evaporation. The components can be assembled directly after dosing the activator and adhesive. The production process can continue immediately, thus reducing cycle times. With these new solvent-free activators, the risks of solvent vapours and their impact on human health and the environment are zero. No extraction systems are required for production, nor are any explosion protection measures necessary. In addition, the fluorescent agents contained in the activators - blue for the DELO-QUICK 5910 and red for the DELO-QUICK 5975 - make it possible to monitor the application process with a camera, thus guaranteeing the quality of the process. In addition, the use of these activators improves the moisture resistance for bonding metals such as stainless steel or aluminium. The DELO-QUICK 5975 is even particularly effective for bonding nickel, which is known to be difficult to bond due to its various coatings.

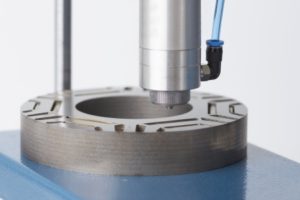

Both activators can be easily dosed and applied by spraying, using a volumetric dispenser or any other type of dispensing system.

» Anaerobic Adhesives » Our News