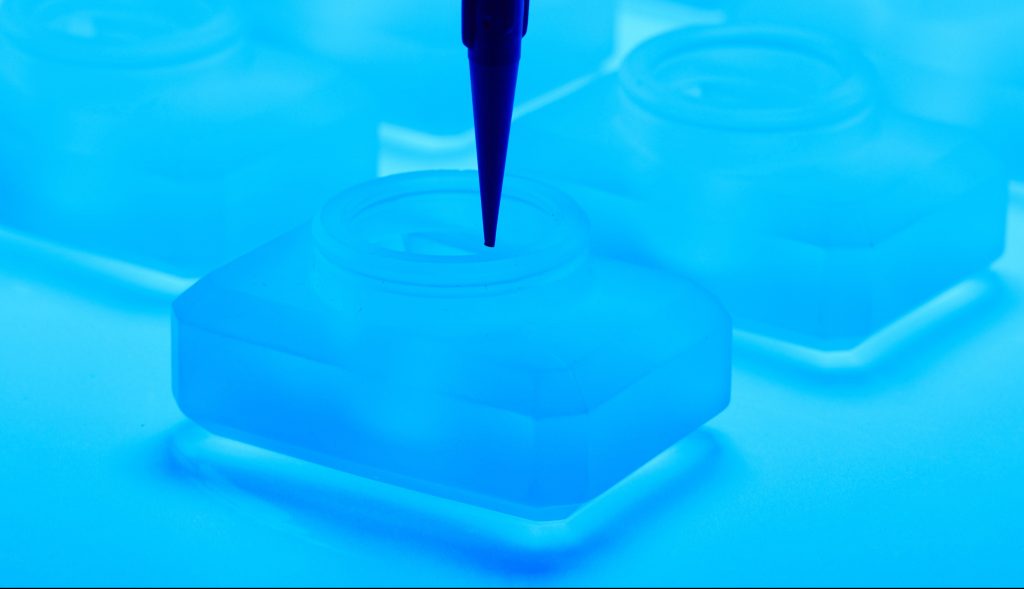

Prepare your surface for optimal adhesion

Do you want to assemble your parts by gluing and do you want to prepare the surface to be glued beforehand? The surface treatment is an essential step in the implementation of a gluing process.

The surface treatment has a different action depending on the nature of the support to be glued. For plastic parts, the surface treatment will increase the “wettability” and the mechanical strength of the assembly. For metals, it will clean the surface of the substrate and make all the parts to be bonded uniform. Surface treatment is also possible on glass and rubber.

Activating and cleaning a surface with atmospheric plasma

SUPRATEC Syneo teams have expertise in the field of industrial bonding and recommend the installation of an atmospheric plasma surface treatment system on your production line. The Plasmabond material guarantees a better adhesion of glue, paint, ink or varnish on a surface ranging from 8 to 70 mm.

Easily integrated into automated (or semi-automated) lines, atmospheric plasma surface treatment provides process security by uniforming the surface of parts entering production.

See our surface treatments