Thanks to UV or two-component bonding

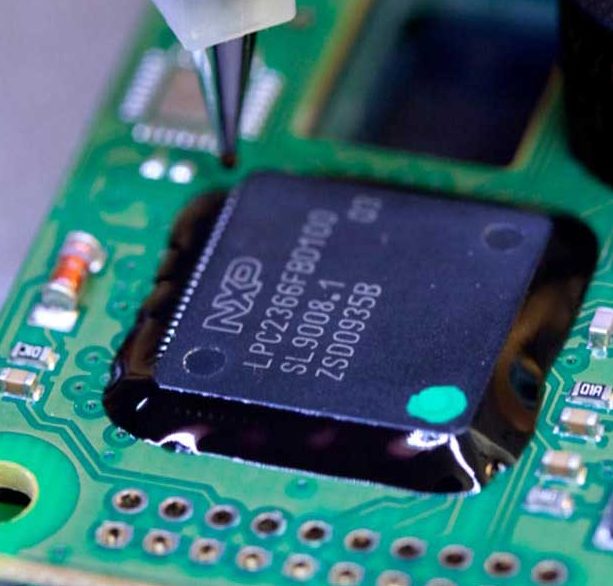

There are many different adhesives specially developed for bonding plastics: the most commonly used adhesives are epoxy, polyurethane and UV adhesives. Epoxy adhesives are also recommended for bonding metal parts. It is therefore a first choice for joining plastic and metal parts together.

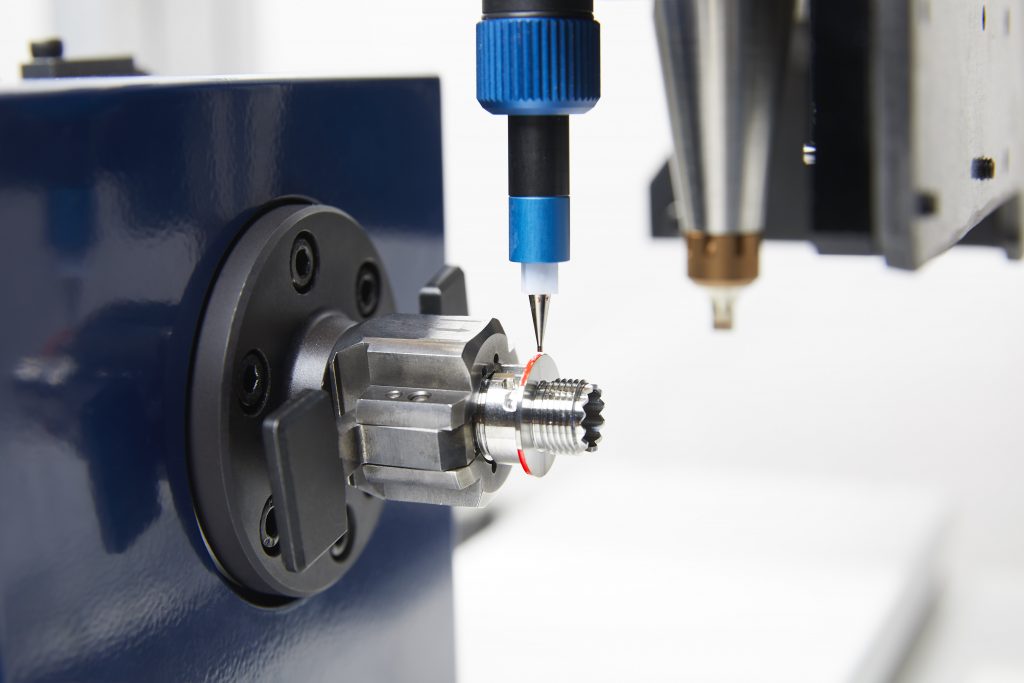

SUPRATEC Syneo will help you to set up or improve your bonding process by assisting you in the various preliminary stages. The choice of adhesive, which is one of these steps, will depend in particular on the surface energy of the plastic and the application itself. Tests can be carried out in our application laboratory (App’Lab) according to your specifications in order to determine with you the best “process adhesive” integrating the technical adhesive(s) adapted to your constraints for efficient industrial bonding.

Discover our App'LabPlastic bonding, a popular process

Plastics have a wide range of industrial applications in terms of visual effect, weight, surface structure and reliability. There are different types of plastic which fall into three main categories according to the temperature at which they can be used over the long term: thermoplastics (resistant to high temperatures, up to 260°C), engineering plastics (up to 140°C), and standard plastics (up to 90°C).

The bonding method of joining plastics is the most common technique to obtain a stable and immediately usable connection. This process requires a high strength joint with strong adhesion of the adhesive to the material and high mechanical strength.

It is also important to note that, although good adhesion is achieved on most plastic materials, pre-treatment of the surface may be advisable in order to improve this adhesion and mechanical strength over time.

See our surface treatments