The transparency of collage, aesthetic and technical issues

Your brand image today is based on the design of your product, its aesthetics and its ability to differentiate itself on the market. Does your final product need to be made of different materials, while maintaining its aesthetics?

Then UV bonding is THE technical solution for your manufacturing process. UV bonding is characterised by the transparency of the final assembly, the strong adhesion of the UV adhesive to the substrate and finally the speed of adhesion for industrial series production.

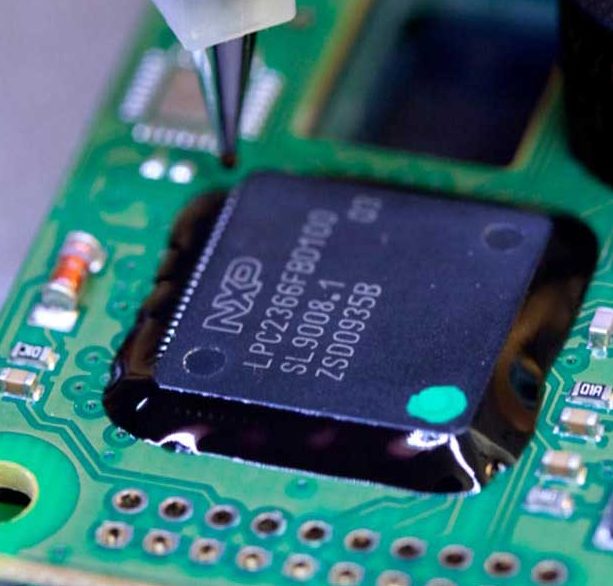

Developed for the needs of the electronics industry, UV bonding offers transparent optics and high strength, for example between glass and other materials. Today, UV bonding is particularly used for decorative glass, optical glass and electronic glass.

See our UV adhesivesMastering UV bonding

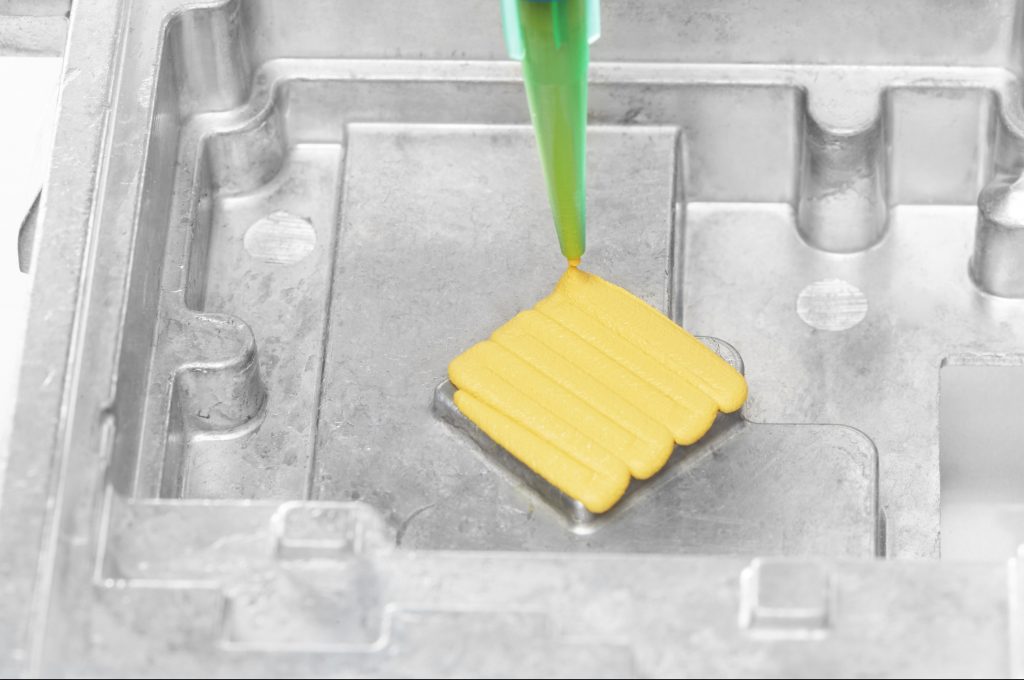

SUPRATEC Syneo has now mastered UV bonding, enabling you to join most materials together. The UV bonding process is simple: a small amount of UV adhesive can be enough to guarantee a stable and durable bond.

Exposure to UV and/or visible light for a short period of time (a few seconds, depending on the thickness of the adhesive and the nature of the substrate) causes the UV adhesive to “cure”. The curing is done by means of UV lamps or ovens.

Able to provide you with a global UV gluing solution, SUPRATEC Syneo will help you choose the transparent glue dedicated to the materials to be assembled, as well as the application, exposure or surface treatment materials.

Optimising the design of cosmetic products