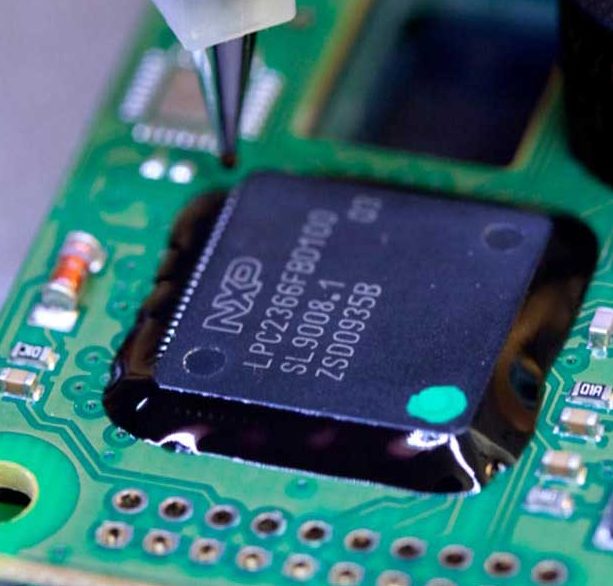

Glob Top and Dam & Fill

Glob Top and Dam & Fill electronic epoxy mounting resins protect electronic components against external aggression and the constraints of using your equipment (humidity, thermal stress and dust). Thanks to these resins, you will be able to control the potting and embedding area by having a repeatable dimensional.

The choice of Dam& FILL or Glob top potting depends on the design requirements of the electronic board. These resins have a complementary role in the tamper-proofing of electronic components in the military, banking or space fields. To enable the Glob top to perform this function, it is important that the 1K or 2K resins are formulated to achieve high TG (180°C) and low Young’s modulus. The polymerisation of these resins will mainly be done by thermal polymerisation. UV curing will save production time.

Volumetric dosing solutions

The application of Dam&Fill and Glob top resins requires dosing equipment that is appropriate for the constraints of these resins. The coating resins are loaded with mineral particles and these are often packaged cold (-18°C). As a result, the fillers do not remain homogeneous during the production time and influence the dosing quality. To remedy this, the use of a TAEHA progressive cavity pump will allow you to ensure the repeatability of your dosing over time but also the longevity of your equipment with specific materials for abrasive products. TAEHA’s volumetric dosing pumps are available for both single component (PCP) and two component (PDP) potting resins.

The choice of a Glob Top or Dam & Fill resin is therefore determined by several factors:

- Design requirements of the electronic board

- Choice of polymerisation

- Choice of dosing material and type of packaging (syringe, cartridge or pot)

This choice matrix will allow us to propose a definitive and relevant solution according to the production volumes.