Technical adhesives for high performance assembly

Different types of adhesives are used for bonding glass to metal. Technical adhesives are the most common for bonding these materials and their use depends on the process you have in place on your production line.

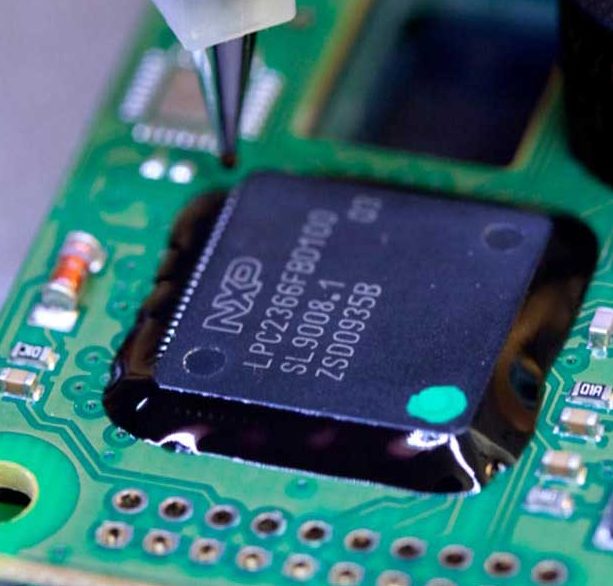

Technical adhesives include single and two-component epoxies, polyurethane adhesives and dual-curing adhesives. These adhesives are particularly effective for the assembly of metal parts, as are anaerobic adhesives, which polymerise on contact with metal ions, even at room temperature.

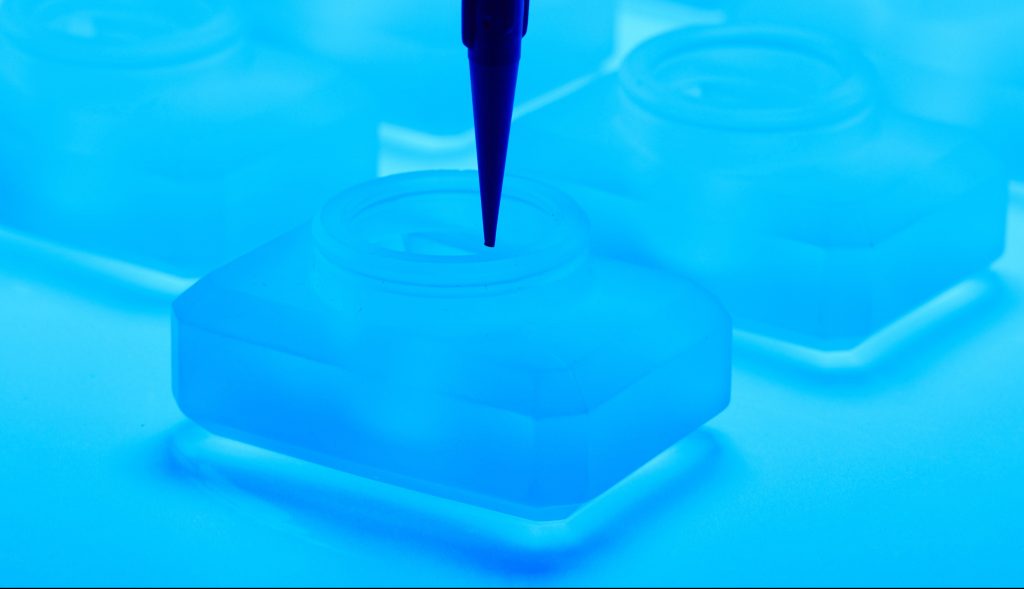

UV adhesives are also used in this type of assembly, particularly for bonding glass. These adhesives allow a fast and transparent bonding, thanks to their refractive index of 1.5, close to that of glass. They are very popular in the cosmetics sector, especially when bonding metal plates to glass bottles.

See our technical adhesivesFast and attractive assembly

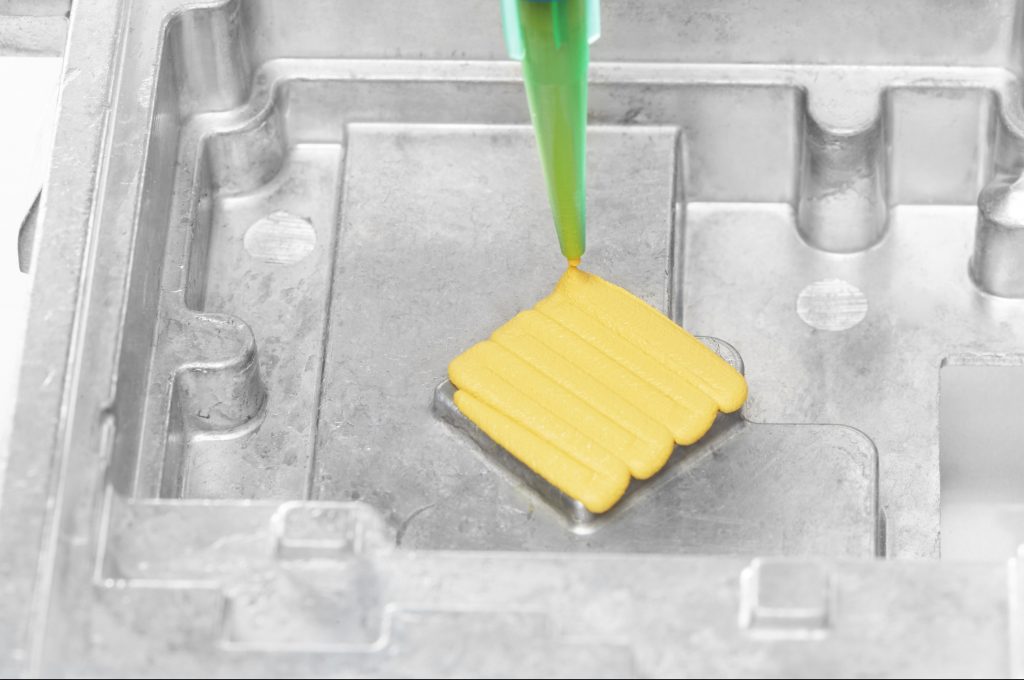

Bonding is a process that guarantees a joint with high mechanical resistance that lasts over time. More aesthetic than other assembly methods, it also allows increased productivity thanks to its simple automation capability. A digitised table is all that is needed to automate the application of adhesive to the part in question. Scanning tables with an integrated UV lamp are also available for a complete automated application and curing process.

Numerous finishers use gluing in the creation of perfume bottles from the most prestigious luxury houses, such as our customer Verescence, whose testimonial you will discover below.

See the application case of Verescence