Metal bonding with epoxy or anaerobic adhesives

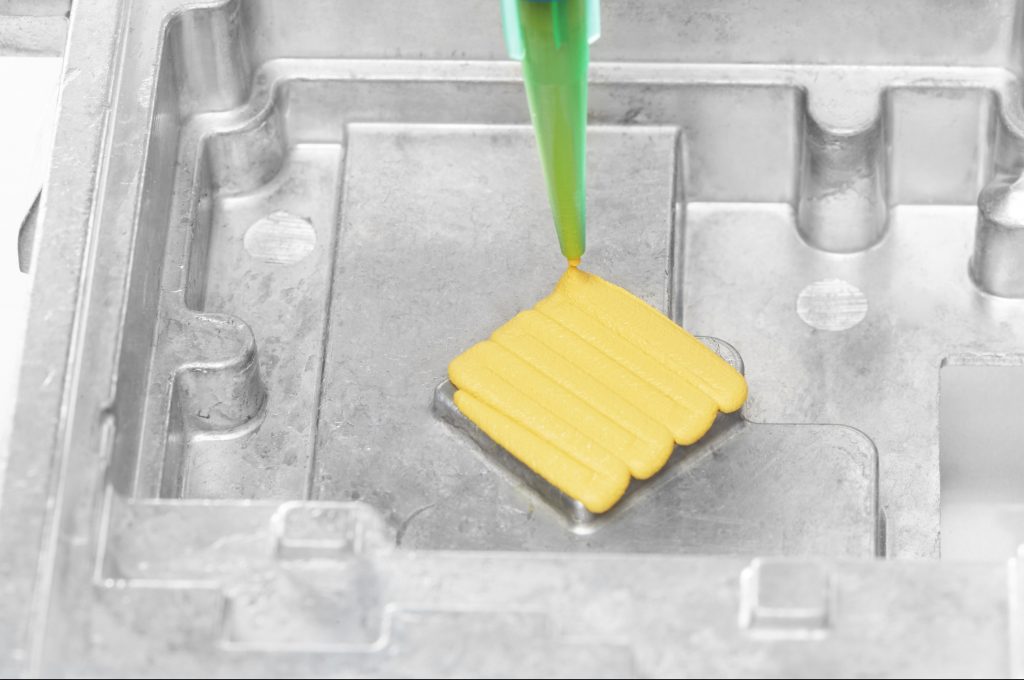

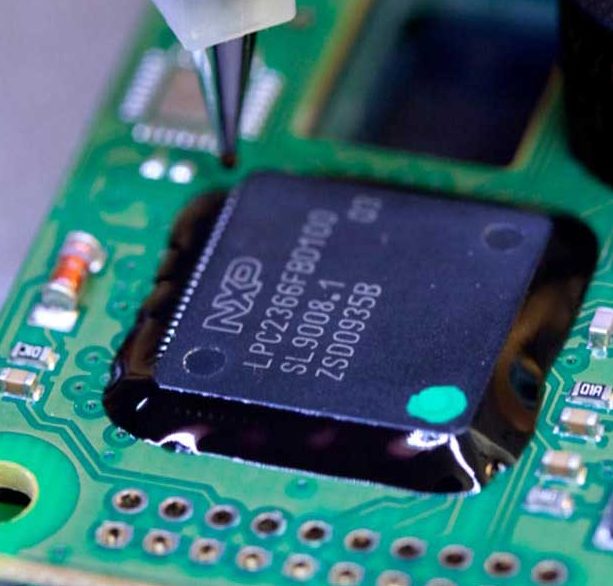

There are different types of adhesives that can be used to join materials in mechanical engineering: so-called technical adhesives such as single- or-two component epoxy adhesives, polyuréethane adhesives and anaerobic adhesives, which cure very quickly in the absence of air and in contact with metal ions.

Anaerobic bonding is achieved very quickly by curing the adhesive at room temperature when in contact with the metal. This hardening can also be accelerated by exposing the adhesive to UV light. The DEMO-ML anaerobic adhesive, proposed by the SUPRATEC Syneo teams, thus offers rapid adhesion in a few minutes and strong resistance to extreme temperatures and chemical products.

See our anaerobic adhesivesJoining metal with glue

Bonding solutions for metal are developed to ensure very high mechanical strength connections, so-called “structural bonding”. Bonding replaces other assembly methods such as welding, screwing and riveting, while providing an additional element: competitiveness.

This assembly technique allows significant productivity gains in terms of production costs, weight of assembled parts and assembly time. Adhesives for metal assembly must have optimised properties for the most diverse applications and constraints: chemical resistance, thermal resistance up to +250°C.

See our technical adhesives