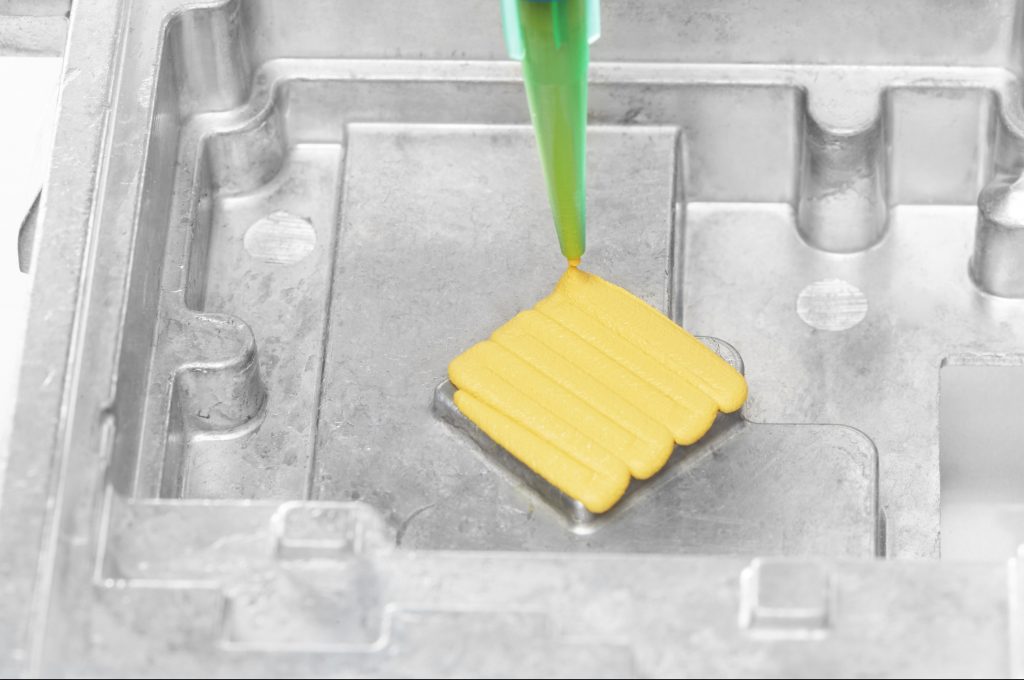

Make identical and homogeneous cords

Unlike a valve or needle valve, screwless dosing systems provide accurate dosing without interrupting production. In addition, product loads do not accumulate in the system. The progressive cavity feeder, commonly known as a screw feeder, consists of a screw, the rotor, and a chamber, the stator. There are different types of materials for the two sub-assemblies depending on the product to be deposited.

Preventing the demixing of grease

Due to its high viscosity compared to oil, grease has a resistance to high temperatures whereas oil would evaporate. Also during the application, the homogeneity of the grease is very important to keep its properties. Pressure blowers do not guarantee this. They bludgeon the product with jolts. The customer has therefore chosen a low-pressure drum emptier which regulates itself with the dosing device by turning its screw regularly and gently until the required pressure is reached.