Rethinking a production process

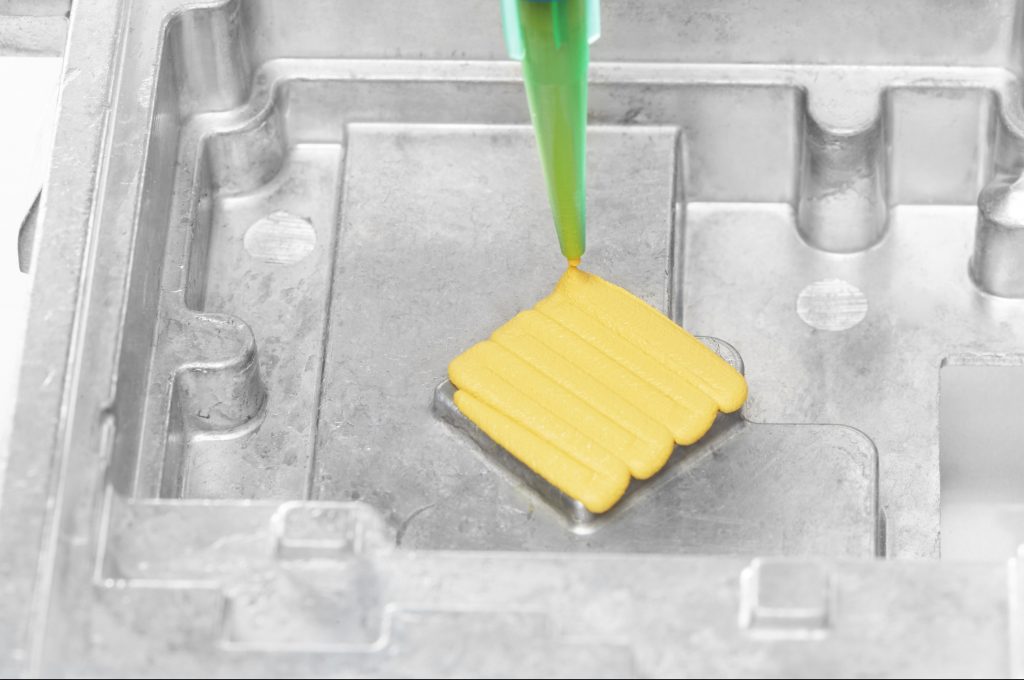

This public lighting manufacturer asked SUPRATEC Syneo to improve its luminaire production line. The initial manual bonding, using silicone, was causing a discontinuous production flow and drying times of over 24 hours.

The implementation of a 2-in-1 solution!

The SUPRATEC Syneo teams have thus contributed their expertise by developing a two-in-one solution! Silicone was replaced by UV glue for rapid and aesthetic bonding, and a special machine was set up to automate the overall process. This complementarity allowed us to reduce the gluing time of a luminaire by 4000%, from 48 hours to 75 seconds! This solution enabled our customer to work in continuous flow, to increase its production rate and its profitability.